Light Guide Stamper

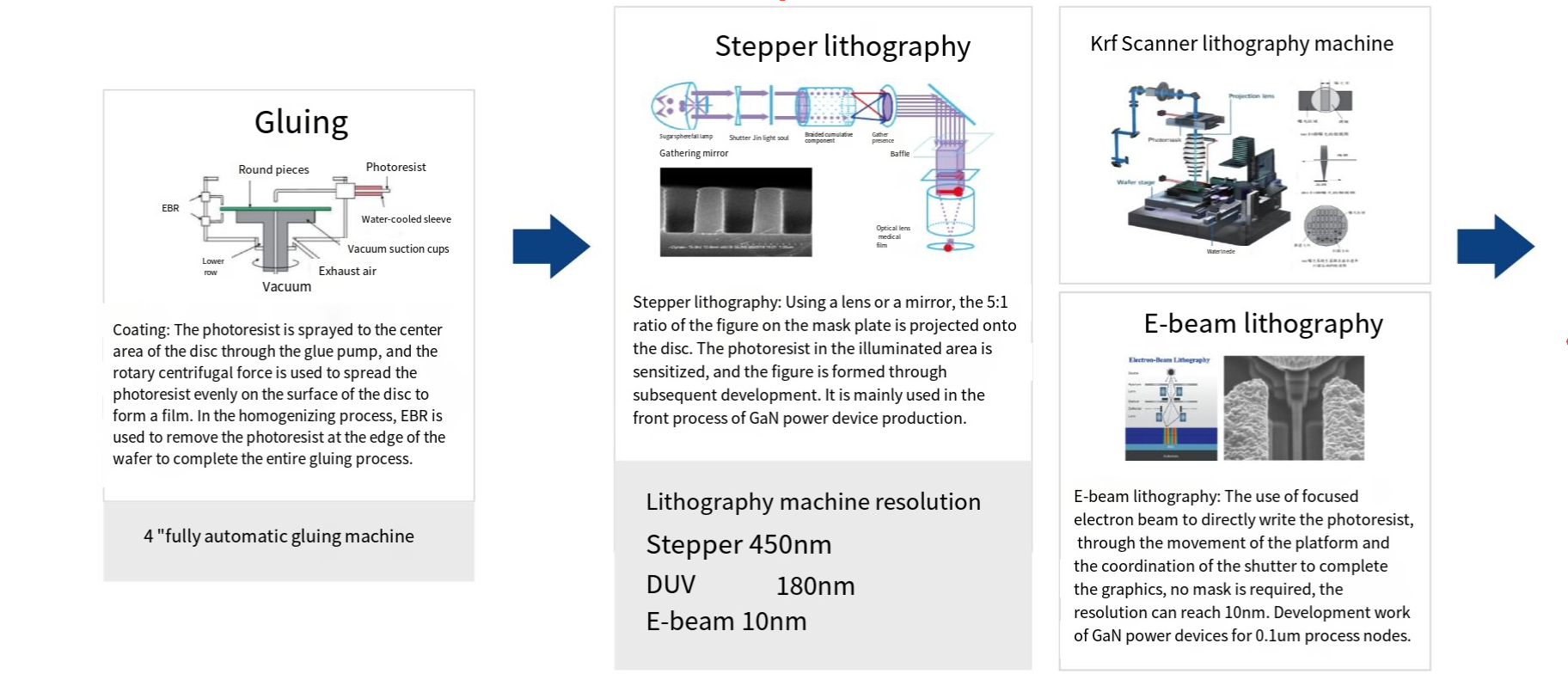

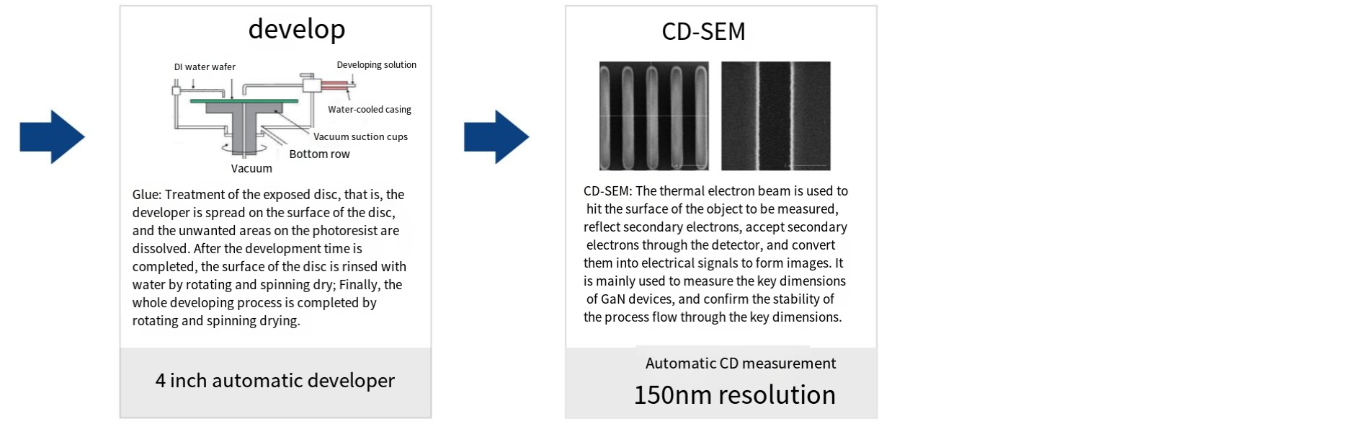

Can provide a variety of short process services, including narrow line width lithography, thinning, cutting, etc., with advanced electron beam direct writing lithography machine, can provide nano imprint template, deep lens and other processing services.

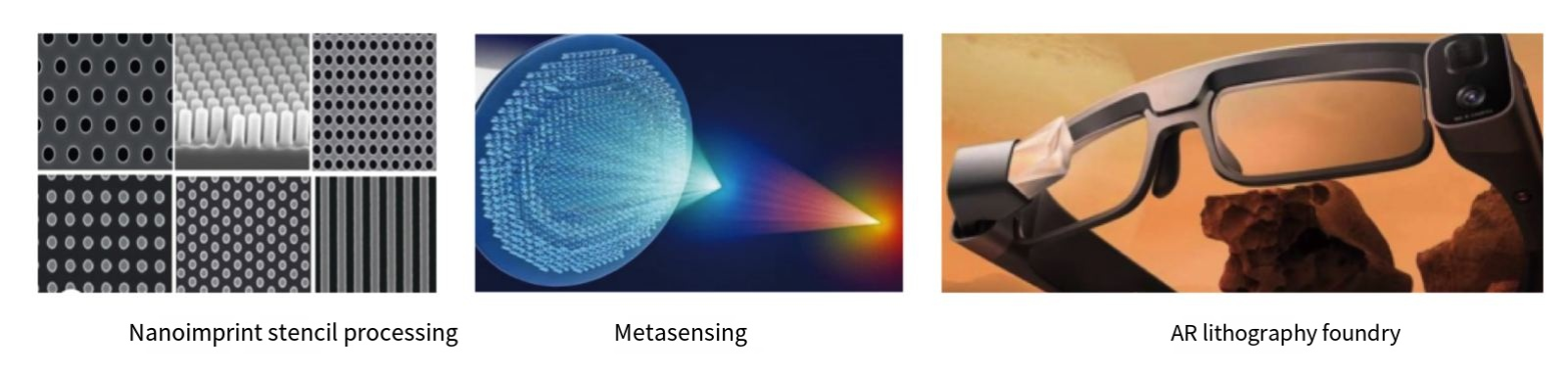

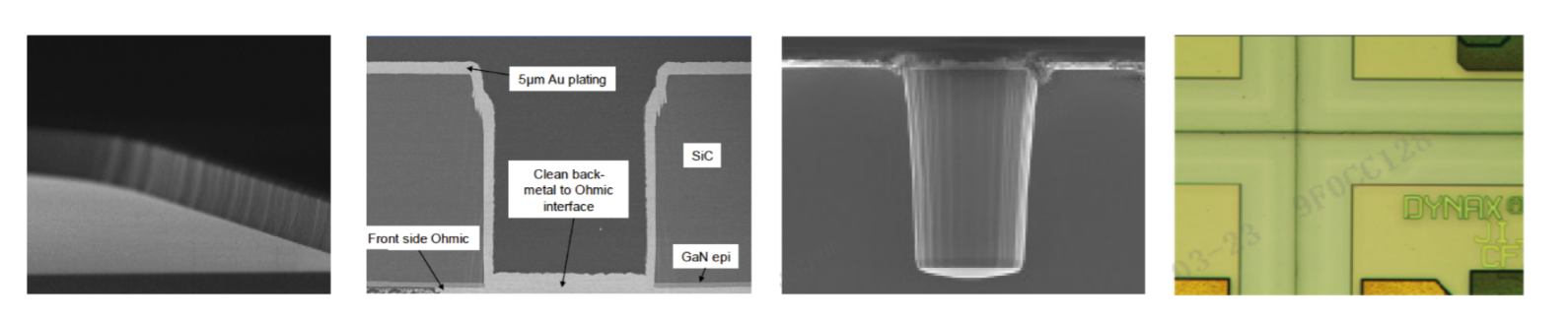

SiC Back finish

SiC through hole etching is a key process for GaN HEMT devices to achieve metal interconnect between front source and pad. The difficulty lies in the fact that 100 micron deep SiC through hole etching can be achieved with a 50 mm open hole size, which requires smooth side wall and no column in the hole after SiC through hole etching. The groove gan through hole etching process is simpler than SiC and requires approximately etching The 2um GaN material layer requires that the through hole is clean after etching, without Pillar, Pit and Trench.

CN

CN